Norton Roadholder forks have been synonymous with exceptional motorcycle handling since the late 1940s, particularly when paired with the legendary Norton Featherbed frame. But were Roadholders genuinely revolutionary — or did clever marketing play a role in their enduring reputation?

The Roadholder name emerged as Norton’s telescopic fork design gained notoriety during the immediate post-war period. While performance gains had traditionally focused on engines, rising speeds — especially on still-unsealed roads — highlighted the growing importance of chassis control and suspension quality.

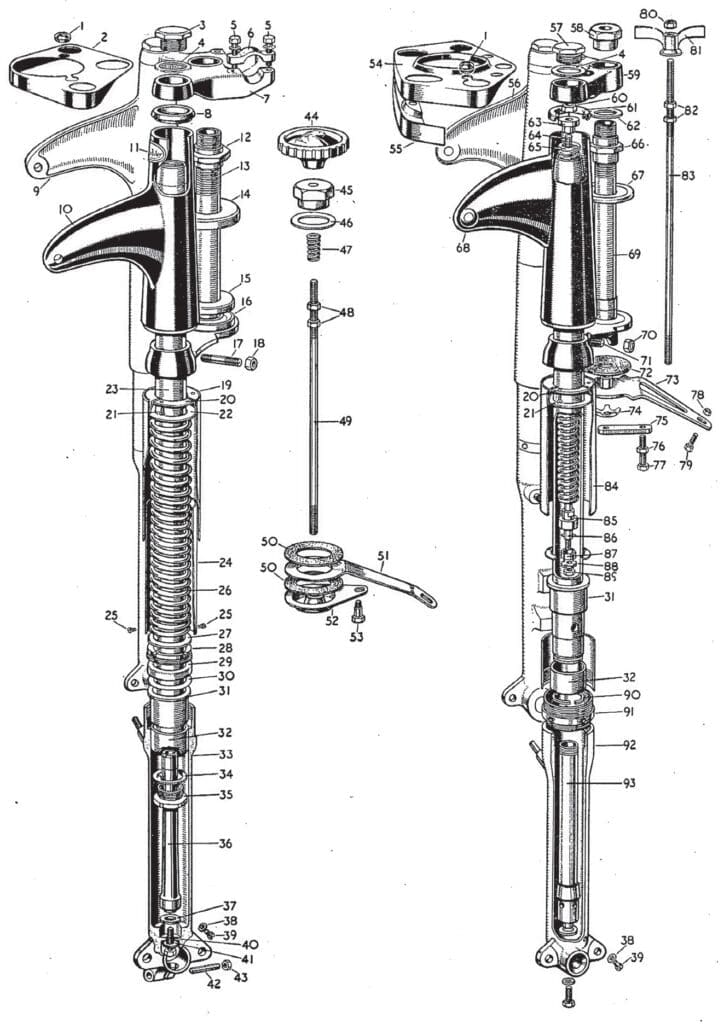

Before the Second World War, most motorcycles relied on girder forks, offering limited damping. During wartime development, Norton engineer Jackie Moore contributed to telescopic fork research, leading to Patent 557,982, applied for in June 1942 by Norton Motors Ltd and managing director Charles Gilbert Smith. Although the patent described a conventional telescopic fork, Norton’s execution focused on strength, stiffness and hydraulic control.

Enjoy more classic motorcycle reading, Click here to subscribe to one of our leading magazines.

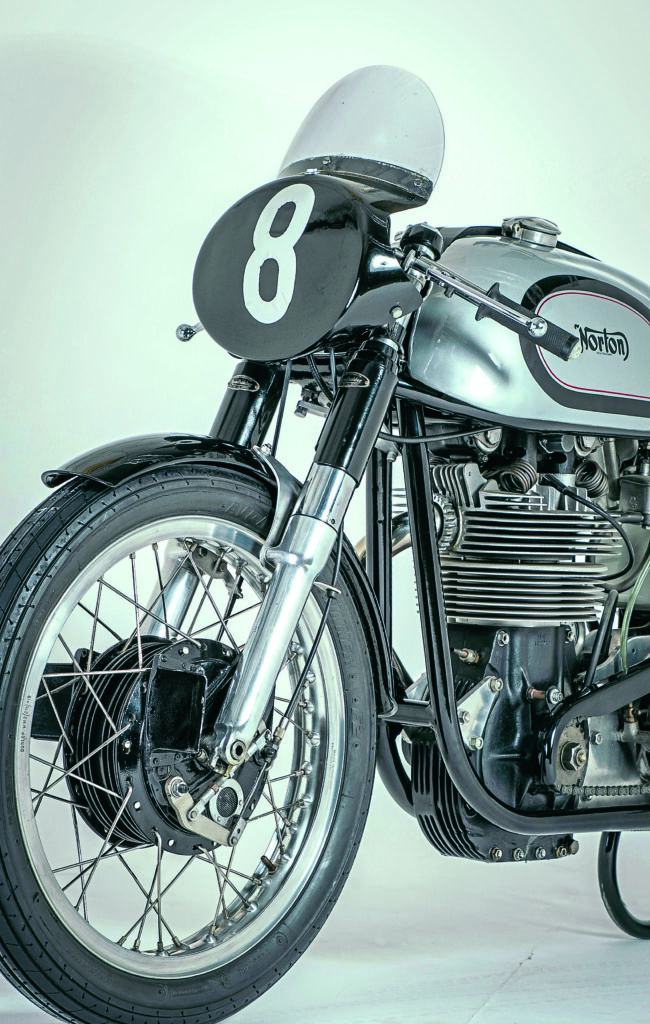

The term “Roadholder” first appeared in Norton literature in mid-1946, ahead of its use on the Manx and International 30M and 40M racing models for the following season. Apart from lower-compression pistons for poor post-war fuel, Roadholders were the only significant update to these machines — and they worked.

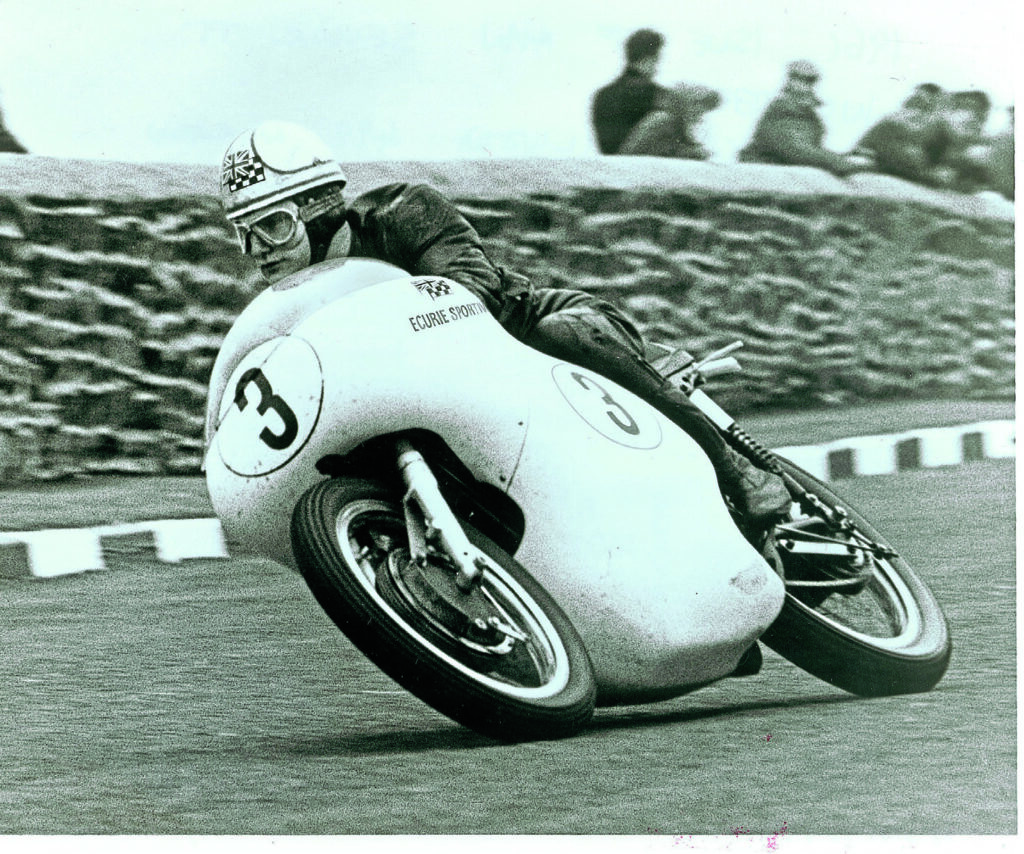

Race success followed, cementing Norton’s reputation for superior handling. The slogan “The World’s Best Roadholder” became inseparable from the forks themselves, and Roadholders were gradually fitted across Norton’s road models as materials and budgets allowed.

Early Long Roadholders (1946–47) offered improved hydraulic control, even on pre-Featherbed frames. With the arrival of the Featherbed frame in 1950, geometry demanded a shorter fork, giving rise to the Short Roadholder, which delivered improved damping characteristics. Later Commando-style Roadholders refined the internal damping further and represented the best factory development of the design.

What truly set Roadholders apart was their robust construction. Large-diameter stanchions, thick yokes, lightweight fork bottoms and substantial bushes reduced flex and unsprung weight. Internally, the damper-rod system — immersed in oil — provided controlled compression and rebound, a layout still recognisable in modern fork designs.

Although early versions could feel limited mid-stroke or harsh at extremes, modern fork oils, renewed bushes and chromed stanchions can dramatically improve performance today. For those seeking ultimate control, modern internals from specialists such as Maxton or K-Tech can transform Roadholders — though the bikes they serve remain over half a century old.

Produced continuously from 1943 to 1978, Norton Roadholder forks marked a pivotal moment in motorcycle design, proving that handling mattered just as much as horsepower — a lesson still relevant today.